Learn

Products

Design

Warranty

For Pros

About

Back

Learn

Back

Products

Shingles

Get Inspired

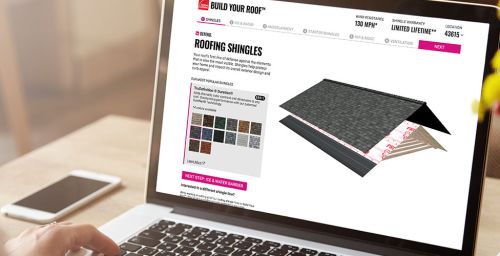

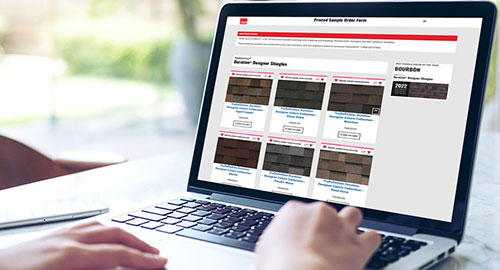

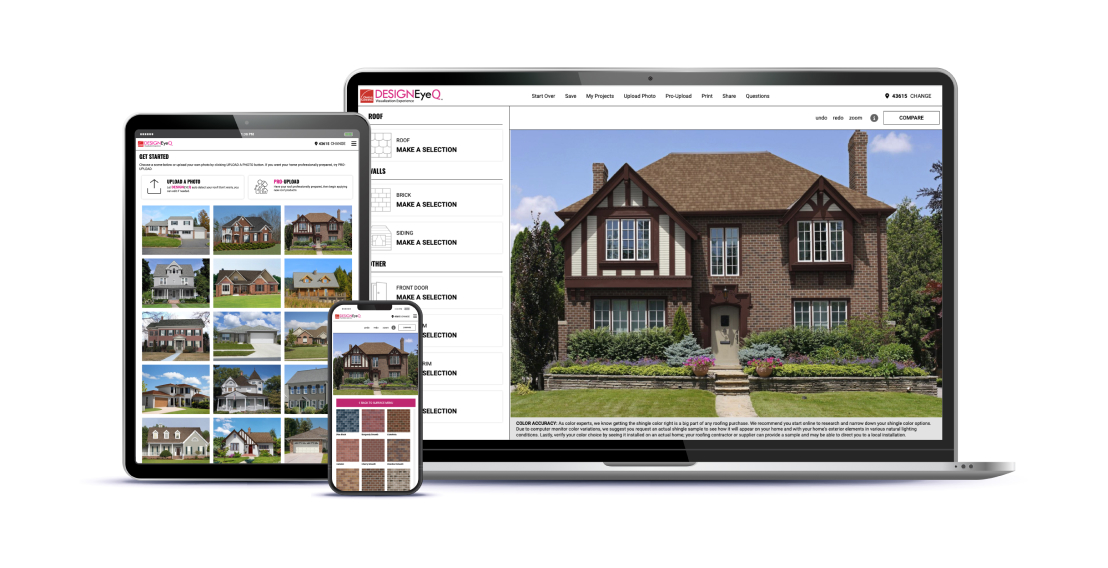

Photo Gallery Build Your Roof | Visualizer 2024 Shingle Color of the YearAsphalt

Trumbull®Weather Resistant Barriers

PinkWrap®System Components

Specialized Shingles

Hip and Ridge Shingles Starter ShinglesUnderlayments

Ice and Water Barrier Synthetic UnderlaymentVentilation

Intake Ventilation Exhaust Ventilation

Low Slope Products

Titanium® and RhinoRoof®

Explore all Components

Back

Design

Back

Warranty

Back

For Pros

Back

About

Our Brand Promise

When you buy Owens Corning roofing shingles, you can rest assured that our commitment to quality is of the highest importance.

Read More

Back

Find a Contractor